Crane Scales - A Comprehensive Guide

Posted by Jon M on Feb 26th 2024

In industrial operations, precision and efficiency are paramount. Whether you're managing a warehouse, construction site, mine, or shipping yard, accurate measurements play a crucial role in optimizing productivity and ensuring safety. Crane scales, which are designed to accurately weigh heavy loads suspended from cranes, hoists and overhead beams, are commonly used in these industry applications among many others. In this guide, we explore the functionality, applications, operational safety and key factors to consider before purchasing a new crane scale.

Understanding Crane Scales

Crane scales are specialized weighing devices engineered to withstand the rigors of industrial environments. Unlike traditional scales that sit stationary, crane scales are attached to lifting equipment or steel beams, such as cranes, hoists, and beam trolleys, allowing for the direct measurement of heavy objects while they are suspended in the air. The process of suspended weighing is often referred to as "overhead weighing".

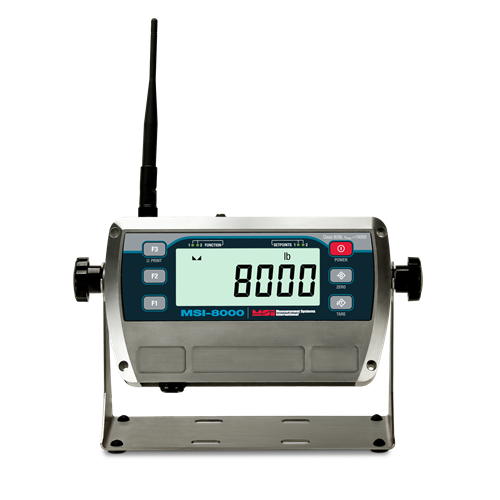

These scales include a load cell, which converts mechanical force into electrical signals, a digital display unit for readouts, and sturdy housing to protect the internal components from damage. Some models may also feature additional functionalities and features such as wireless connectivity for data transmission, programmable settings and intrinsic safety ratings for use in environments exposed to the risk of explosion.

Applications of Crane Scales

Crane scales are used across various industries wherever there is a need for heavy-capacity weighing and transporting loads from one location to another. The ability to weigh overhead is a significant advantage for exceptionally large or heavy materials that standard weighing scales can't accommodate.

Here are some real-world applications where crane scales are used:

Material Handling and Logistics: Crane scales are extensively used in warehouses and distribution centers for weighing goods, shipping containers, and oversized packages before loading or unloading.

Construction and Engineering: In construction sites, crane scales play a vital role in lifting and positioning heavy materials such as steel beams, precast concrete elements, and machinery with precision, ensuring compliance with weight limits and safety regulations.

Manufacturing: Within manufacturing facilities, crane scales facilitate inventory management, quality control, and product testing by accurately measuring raw materials, finished goods, and components during production processes. They are very common in steel mills where large steel blanks and rolled steel are suspended and weighed.

Shipping and Transportation: Shipping yards and ports rely on crane scales to determine the weight of cargo containers and bulk shipments, enabling efficient loading onto vessels and ensuring compliance with weight restrictions for road and rail transport.

Commercial Fishing: Crane scales are available for use in marine applications including the commercial fishing industry. They are used to accurately weigh large amounts of seafood to determine catch weights and to stay within any imposed limits. Crane scales are also used at docks and tender boats to calculate total weight for commercial transactions.

Aviation: Crane scales are utilized in the testing and certification of aircraft components to verify their weight and performance characteristics. This includes testing the weight-bearing capacity of components such as galleys and cargo compartments to ensure they meet regulatory standards and safety requirements.

Mining: In mining, various raw materials such as ores, minerals, and rocks are extracted from the earth's surface or underground. Crane scales are used to accurately weigh these materials as they are loaded onto trucks, conveyor belts, or other transportation mediums for further processing or transportation to processing plants. They help ensure that lifting equipment such as cranes and hoists do not exceed their maximum load capacities, thereby preventing accidents, equipment damage, and potential injuries to personnel.

Factors to Consider When Buying a Crane Scale

Investing in the right crane scale entails careful consideration of several factors to ensure optimal performance and suitability for specific operational requirements. These include the environment in which they will be used, functions needed to perform operations efficiently and communication options for data management.

Weight Capacity: Determine the maximum weight capacity required for your application, ensuring that the crane scale can accommodate the heaviest loads typically encountered in your operations. It's advisable to choose a scale with a capacity higher than your anticipated maximum load to prevent overloading.

Accuracy and Precision: Assess the scale's accuracy specifications, typically expressed as a percentage of the full-scale capacity. For applications demanding precise measurements, opt for scales with higher accuracy ratings. Additionally, consider factors such as resolution—the smallest increment of weight that the scale can display—especially when dealing with small or incremental measurements.

Environmental Protection: Given the harsh environments in which crane scales operate, prioritize models constructed from robust materials such as stainless steel or aluminum with reinforced housing to withstand impacts, moisture, and dust. Look for scales with ingress protection (IP) ratings indicating their resistance to water and dust ingress.

In environments where explosive hazards exist, intrinsically safe crane scale should be considered. Intrinsically safe scales are often used in manufacturing and industrial applications such as chemical manufacturing, mining, and energy.

Display and Interface: Consider the visibility and readability of the scale's display unit, especially in poorly lit or outdoor environments. Some models offer backlit displays with large digits for enhanced visibility. Additionally, assess the user interface for ease of operation, intuitive controls, and accessibility of essential functions.

Remote Displays: To enhance visibility and display weight measurements in other locations, consider the option for wireless remote displays. In some applications, it may be necessary for multiple operators to view the readout in different areas of the facility. Some remote displays also act as a controller, allowing wireless operation of the crane scale.

Power Source and Battery Life: Evaluate the power source options available, such as rechargeable batteries or main power. Opt for models with long-lasting battery life to minimize downtime and ensure uninterrupted operation during extended work periods.

Compliance: Verify that the crane scale complies with relevant industry standards and regulations, including safety standards like OSHA, ANSI, ASME and others. For commerce, or legal-for-trade applications, look for NTEP (National Type Evaluation Program) approved models.

Connectivity: Explore additional features that align with your specific needs, such as wireless connectivity for data logging, printing, remote monitoring, and integration with management systems. Some advanced models may offer Bluetooth or Wi-Fi connectivity for seamless data transfer to compatible devices.

Safe Operation of Crane Scales

Operating a crane scale requires careful attention to safety to prevent accidents, injuries, and equipment damage. In any location where suspended loads are present, it is imperative to ensure safety protocols are in place. Frequent training is necessary to protect operators from unnecessary injury, or worse. It is also recommended to display signage, signal lights and incorporate alarms in areas where these heavy-capacity crane scales are being used.

Here are some safety considerations to make when using crane scales:

Proper Installation and Attachment: Ensure the crane scale is securely attached to the lifting equipment, such as cranes, hoists, or beam trolleys following manufacturer's guidelines and recommendations. Use appropriate rigging hardware, shackles and attachment points to prevent slippage or detachment during lifting operations. If hanging from a structure such as a steel beam, be sure that the structure can withstand the expected loads being weighed. Failure to ensure structural integrity could lead to damage, injury and costly repairs.

Weight Capacity Limits: Always adhere to the specified weight capacity limits of the crane scale and avoid overloading it beyond its rated capacity. Verify the weight of the load before lifting and ensure it falls within the scale's capabilities to prevent structural failure, damage or injury.

Regular Maintenance: Conduct routine inspections of the crane scale, including visual checks for signs of wear, damage, or corrosion. Inspect shackles, cables, electronics and connections for integrity and perform regular maintenance as per the manufacturer's recommendations to ensure optimal performance and safety.

Calibration: Regularly calibrating a crane scale not only maintains accuracy and reliability, but it also helps to prevent accidental overloading. Follow established calibration procedures and schedule calibration checks at recommended intervals to ensure compliance with industry standards and regulations.

Safe Lifting Practices: Implement safe lifting practices and procedures, including proper load attachment, balanced loading, and controlled lifting speeds. Avoid sudden movements or jerks that can induce stress on the crane scale and compromise its integrity.

Clear Communication: Establish clear communication protocols among personnel involved in lifting operations, including crane operators, riggers, and ground personnel. Use standardized hand signals, communication devices, signal lighting and alarms to coordinate movements and ensure everyone is aware of their roles and responsibilities.

Emergency Procedures: Familiarize yourself with emergency procedures in the event of equipment malfunction, overload situations, or accidents. Have contingency plans in place, including emergency stop procedures, evacuation routes, and protocols for addressing potential hazards or injuries.

Training and Competency: Provide comprehensive training and competency assessments for personnel involved in operating crane scales, including proper usage, safety protocols, and emergency response procedures. Ensure operators are adequately trained and qualified to perform their duties safely and efficiently.

By prioritizing safety considerations and adhering to established protocols and guidelines, operators can mitigate risks associated with operating crane scales and ensure the safety of personnel, equipment, and surrounding infrastructure during lifting and weighing operations.

Proper Maintenance of a Crane Scale

Proper maintenance of an industrial crane scale is essential to ensure its reliability, accuracy, longevity and safety. Whenever heavy-loads and potentially hazardous materials are being handled, it is imperative to ensure that all equipment is in optimal condition. There are several maintenance best-practices to consider, of which we'll outline here.

Regular Inspection: Conduct visual inspections of the crane scale before each use to check for any signs of damage, wear, or corrosion. Pay attention to load cells, cables, shackles, connectors, and the scale housing for any abnormalities that may affect performance.

Calibration: Schedule regular calibration checks according to the manufacturer's recommendations or industry standards. Calibration ensures the accuracy of weight measurements and may involve adjustments to compensate for any drift or deviations over time.

Battery Maintenance: If the crane scale is battery-powered, monitor the battery status regularly and replace batteries as needed to maintain reliable power supply. Follow proper battery handling and charging procedures to prolong battery life and prevent downtime.

Rigging and Attachment Inspection: Inspect rigging hardware, attachment points, and lifting accessories used in conjunction with the crane scale to ensure they are in good condition and meet safety standards. Replace any worn or damaged components promptly to prevent accidents during lifting operations. This is also a good time to inspect any equipment that is used in conjunction with your crane scale, including hoists, cranes and other lifting equipment.

Environmental Considerations: Consider the operating environment of the crane scale and take appropriate measures to protect it from extreme temperatures, moisture, dust, or corrosive substances. Use protective covers or enclosures when operating in harsh conditions to prolong the scale's lifespan.

Documentation and Record-Keeping: Maintain thorough records of maintenance activities, calibration checks, and any repairs or modifications performed on the crane scale. Keep track of service schedules and document any issues or discrepancies for reference and traceability.

Conclusion

Crane scales are necessary instruments for industries reliant on precise weight measurements for operational efficiency, safety, and compliance. By considering factors such as weight capacity, accuracy, durability, safety features, and connectivity options, you can make informed decisions when selecting the right crane scale for your application. Investing in high-quality, reliable crane scales not only enhances productivity but also ensures the safety of personnel and assets, making it a worthwhile investment for any organization operating in heavy-duty environments.

Scales Plus is a leading distributor and service provider of heavy-capacity crane scales. Need help choosing the right system? Do you need technical support? Contact Scales Plus today!