Types of Load Cell Cable and Where To Use Them

Posted by Josh M on Dec 18th 2018

You know what load cells you need for your next project (or maybe you don't, we can help with that) and now you need to integrate them into the rest of your system. There are many things to consider when building custom weighing applications but today we are only going to focus on the load cell cables. What type of load cell cable are you going to need to get the job done right? You’ll have to consider a number of things, including length, temperature, and other environmental factors.

Simply put, load cell cables act as both a power and communication channel, bridging the indicator and load cells together. Power originates from the indicator through the excitation wires in a load cell cable. The load cell acts as a transducer that then creates an electrical signal proportional to the force applied to it. This proportional electrical signal is then relayed back to the indicator which displays the numerical weight based on the signal strength. So what types of load cell cables are there?

4-Wire Load Cell Cable

The most common type of load cell cable is the 4-wire type. Why is it called 4-wire? It has 4 wires (duh) including power + (sometimes referred to as excitation), power -, signal +, and signal -. The excitation wires deliver an electrical current to the strain gauge (a type of resistor) in the load cell, typically between 5 and 10 volts. As the strain gauge deforms from a mass placed on the load cell, the resistance changes. The output to the indicator is typically between 0 and 30 millivolts and is sent back through the signal wires. This signal is then converted inside the indicator to display a numerical weight.

Rice Lake 4-Wire Standard Load Cell Cable

4-wire cable is typically used in short lengths from the scale base or junction box to the indicator. To understand why we have to look at a little physics. The resistance of a load cell cable varies with length and ambient temperature. As the cable's length and temperature increase, so does its resistance. 4-wire cables are typically used in shorter lengths as a thicker cable is needed to contain the voltage drop over longer spans of wire. The table below shows the recommended wire gauge over various lengths.

Almost all commercial scales that have an indicator attached use 4-wire cable because it's cheaper and the length required is minimal. Additionally, because 4-wire load cell cable is calibrated to its length and thermally compensated, it should not be shortened. This generally voids warranties as well on standalone scales. Keep in mind, if a 4-wire cable has to be replaced, the system generally needs to be calibrated again.

So what does one do if you have to run the cable over a long distance or in unpredictable environments? You either increase the size of the cable or switch to a 6-wire load cell cable. Over long distances, 6-wire is the cheaper option and provides more accuracy in the system.

6-Wire Load Cell Cable

Just as with the naming convention of 4-wire cable, 6-wire cable has 6 wires (again, duh). They have all the same wires as the 4-wire cable but also have two additional sense wires, both positive and negative. These sense wires are used to factor in the resistance changes and subsequent voltage drops over the length of the cable.

Unlike the 4-wire cable, the sense wires in a 6-wire cable allow the indicator to adjust the output voltage with an amplifier to compensate for voltage drops over long distances or varying temperatures. This is important as 6-wire cables have no temperature compensating system which means that technicians have the ability to cut or extend a length of 6-wire cable without compromising the cable or re-calibrating the entire system.

Rice Lake 6-Wire Standard Load Cell Cable

6-wire cable is most commonly used in commercial applications where multiple load cells are employed. A hopper or tank system may use four load cells with one under each foot to measure weight. These four load cells are then connected to a junction or summing box before the indicator. The summing box adds the signals from each load cell together which is then sent to the indicator to determine the weight based on the indicators calibration.

6-wire cable is used in these types of applications because of the ability to repair sections without re-calibrating the system, to run long lengths of wire, and to adjust to temperature changes in uncontrolled environments. Of course, there are other things to keep in mind besides when choosing a load cell cable. Let's take a look at the shielding.

Load Cell Cable Shielding

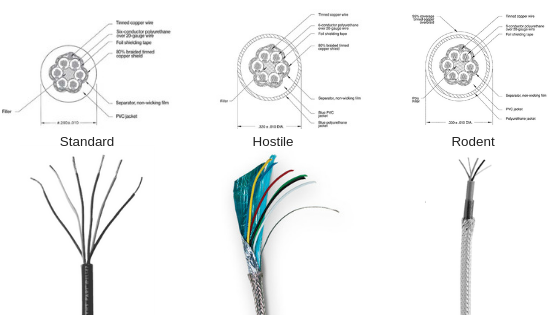

Standard Cable

Standard load cell cable typically has a foil tape shielding, a braided tinned copper shield, and an outer PVC jacket to insulate and protect the wires. This type of load cell cable is best used in controlled environments or when replacing existing factory wire that has been damaged. This cable is generally the most economical as well.

Hostile Environment Cable

Hostile Environment load cell cable is best suited in extreme environments where the cable may be exposed to chemicals or regular abrasion. This cable is similar to standard wire except that it has an additional polyurethane jacket that wraps around the PVC jacket. The polyurethane protects against many chemicals including fuels, salts, and ether. The extra layer helps protect the cable from abrasive materials, reducing the chance of de-jacketing.

Intrinsically Safe Cable

Intrinsically safe cable is for use in environments that deal with explosive materials including fuel, gunpowder, paint, and other flammable products. This cable typically has the same double jacketing as a hostile environment cable to protect against chemicals and abrasions. The jackets are also colored blue to meet industry standards for intrinsically safe wiring.

Rodent Protection Cable

Just as the name implies, rodent protect cable protects against pesky rats and mice from gnawing and damaging lengths of wire that may be costly to replace. This type of cable differs in two ways from the other types of cable. The braided shield is the outermost layer of the cable (rather than inside the PVC jacket) and is coated with a chemical that leaves a bad taste in the mouths of rodents.

These two distinct differences offer the best protection from rodent damage when it can't be avoided by other means. This extra protections also costs a premium price compared to the other types of cable we previously discussed. Check out how Scales Plus has you covered with Rice Lake's Rodent Protection cable.

Conclusion

Whether you're replacing a damaged load cell cable or setting up a custom application, choosing the right cable is important. Although 4-wire load cell cable is the most commonly used and economical, it is worth considering if a 6-wire cable is better for your application. As a general rule, 4-wire is better for short runs or replacing a damaged line, whereas a 6-wire cable is better for longer runs in uncontrolled environments. Whatever you need, Scales Plus has the right cable for your system. If you're still unsure which cable is right for your needs, reach out to us via chat or phone and our scale technicians can point you in the right direction.