What are Calibration Weight Classes?

Posted by Josh M on Feb 13th 2024

One of the most common questions we get related to calibrating scales is "what calibration weight do I need?" There is much to unpack with this question and varies greatly depending on the user's application. Most people know how much weight is required to properly calibrate their scale, but many are unsure of what class is needed or why they matter.

Calibration weights, also referred to as mass standards, are assigned a class based on their accuracy or tolerance. These tolerances are aligned with the type of scales, balances or mass standards that are being calibrated. Using the correct class is necessary to properly calibrate a scale and ensure accurate results.

There are several prominent governing bodies that determine calibration classes; NIST, ASTM and OIML. Each organization has their own set of standards and requirements. ASTM and OIML are recognized globally, while NIST is an organization under the United States Department of Commerce.

NIST

The NIST, or National Institute of Standards and Technology, promotes " U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve our quality of life." Their vision includes creating and maintaining measurement solutions and standards in the US.

NIST Class F

NIST Class F calibration weights are no longer available for legal metrology use as of January 1st, 2020. Mass standard manufacturers have switched these weights to ASTM Class 6 and ASTM Class 7 classifications and no longer offer NIST Class F as an option.

Learn more about the change to NIST Class F standards and Handbook 105-1.

ASTM

ASTM International (formerly American Society for Testing and Materials) is a non-profit organization "that provides a forum for the development and publication of international voluntary consensus standards for materials, products, systems, and services." This non-governmental agency has set forth 10 classes for calibration weights. As the number of the class increases, the tolerance allowed also increases.

Given that ASTM is the most commonly use class system in the United States, we will continue by outlining the various ASTM calibration weight classes.

ASTM Class 7

Primarily used in industrial applications that require rough measurements, ASTM Class 7 has the highest tolerance allowable in the ASTM classification system. Calibration weights with an ASTM Class 7 are suitable for Class III, Class IIII, and non-designated scales like floor scales, shipping scales, and other industrial devices.

ASTM Classes 4 - 6

ASTM Class 4, ASTM Class 5, and ASTM Class 6 calibration weights are primarily used to check and calibrate Class III, IIIL, and unmarked scales. Precision balances and those scales found in student laboratories typically require calibration weights within these classes. These scales typically have readability, or divisions, lower than 0.1 grams (i.e., 0.5g, 1g, etc.).

ASTM Class 3

Moderate precision balances, or those with readability from 0.1 to 0.01 grams, generally require an ASTM Class 3 calibration weight. These types of scales are commonly found in commercial laboratory environments.

ASTM Class 2

Higher precision balances, or those with readability between 0.01 and 0.001 grams (1 milligram), require an ASTM Class 2 weight for calibration purposes. High precision balances are used in the pharmaceutical and chemical compounding industries.

ASTM Class 1

Analytical and semi-micro balances have readabilities of 0.1 mg and 0.01 mg respectively. It is recommended to use an ASTM Class 1 weight when calibrating devices that can weigh out to a fraction of a gram. ASTM Class 1 weights may also be used as references when calibrating other weights with higher tolerances. Users should wear gloves or tweezers when handling these weights as any oils or dirt from their hands can alter the weights' tolerances.

ASTM Class 0 - 000

Almost exclusively, metrology laboratories use ASTM Class 0, ASTM Class 00, and ASTM Class 000 as reference standards for calibrating other weights. They are the most expensive weights available in the market. Extensively controlled environments are required when using these classes of calibration weights because of their exceptionally tight tolerances.

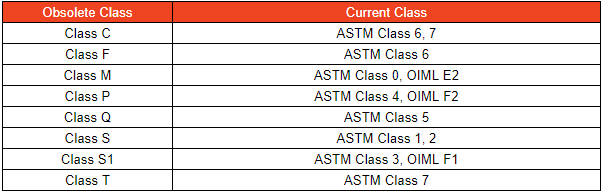

Obsolete Classes

Below is a useful conversion chart to equate obsolete classes with current standards, including the recent changes to NIST Class F weights. This information is updated and current as of February 2024.

Calibration Weight Manufacturers

The two most prominent manufacturers of calibration weights in the U.S. market are Rice Lake Weighing Systems and Troemner. Each of their mass standards are meticulously calibrated in highly-controlled environments and sophisticated metrology labs. Both brands offer the entire range of weight classes, from cast iron ASTM Class 6 and 7, to ultra-precision ASTM Class 000. Scales Plus is a leading distributor of Rice Lake and Troemner products.

Conclusion

Whether in manufacturing, agriculture, food processing or biotechnology, almost every industry uses scales at one point or another in their operations. With that comes the need for calibrating and maintaining those scales to ensure accuracy and reliability. Properly calibrating a scale requires knowing which calibration weight is sufficient for the application and scale type.

If you need help choosing the right calibration weight, contact us today. The team at Scales Plus is prepared to help with extensive knowledge and experience within the field of calibration.

We've updated this blog as of February 2024 to include the most up-to-date information regarding calibration weight classes.